Related Searches

Gasket Types, Types of gaskets pdf, Flange gasket types, Metallic gasket types, Spiral wound gasket types, How many types of gasket, Gasket types name, Types of gasket material, Gasket types images, Types of gaskets in piping

Gasket Introduction

Gaskets are essential mechanical sealing elements used to form a stable seal between two surfaces or flanges, ensuring a leak-proof seal under a variety of operating conditions. Gasket plays an important role in preventing fluid leakage from flange joints and is widely employed in industries such as oil and gas, petrochemical, pharmaceutical, and food processing.

Gasket Types

There are three main Gasket Types are available:

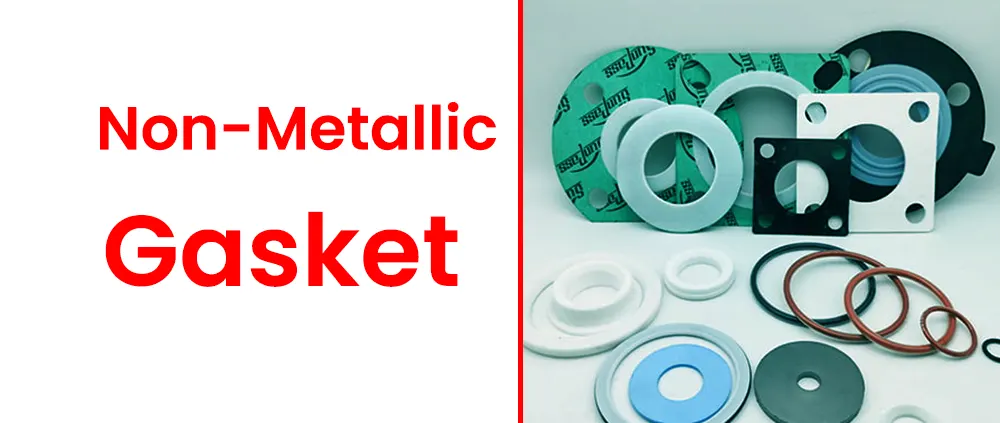

Non-Metallic Gaskets

These gaskets are made of flexible materials such as graphite, rubber, Teflon (PTFE), compressed non-asbestos fiber (CNAF), and ceramic fiber. These are commonly known as soft gaskets and are suitable for flanges of lower-pressure classes, such as classes 150 and 300, as well as for low-temperature applications. Non-metallic gaskets are cost-effective and come in full-face or inside bolt circles.

Metallic Gaskets (Ring Joint Gaskets / RTJ Gaskets)

It is Made from materials such as soft iron, low carbon steel, stainless steel, Monel, and Inconel, metallic gaskets are used in flanges of high-pressure classes, typically above class 900, and also for high-temperature applications. These gaskets require high-tension bolting and are known for their strength and reliability.

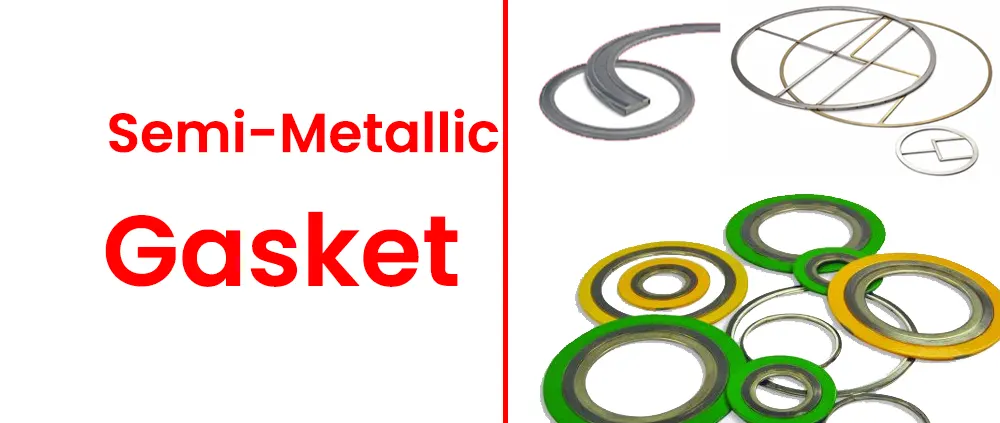

Semi-Metallic or Composite Gaskets

As the name suggests, these gaskets combine both metallic and non-metallic materials, offering a wide range of combinations to suit different service requirements. Common types of composite gaskets include Spiral wound gaskets, Metal jacketed gaskets, and KammProfile gaskets. They are a cost-effective alternative to metal gaskets, used in a wide variety of pressure and temperature services.

Spiral wound gasket

This is one of the most widely used composite gaskets (Semi-Metallic gasket). It consists of inner and outer rings with a curved layer of filler material, usually graphite or PTFE, surrounded by curved strips of stainless steel or other exotic material. These gaskets are suitable for a wide range of pressure and temperature classes.

KammProfil gaskets

It consists of a solid metal core with concentric grooves, layered with a filler material such as graphite or PTFE. They provide superior blowout resistance and are used in a variety of service fluids and operating pressure-temperature classes.

Metal jacketed gaskets

gaskets encapsulate the soft fill material in a thin metal jacket, making them ideal for heat exchangers, shells, channel and cover flange joints as well as valve body bonnet joints.

Selecting the correct gasket material is critical to ensure optimum performance. Non-metallic gaskets are suitable for low-pressure and temperature applications, while metallic gaskets excel in high-pressure and high-temperature scenarios.

Finally, gaskets are indispensable components that play a vital role in maintaining a leak-proof seal in industrial applications. Understanding the different types of gaskets and their appropriate applications can help engineers and professionals make informed decisions when designing and installing flange joints.

Gasket Materials

Non-Metallic Gasket is manufactured from flexible materials. Such as

- CAF

- CNAF (Compressed Non-Asbestos fiber)

- PTFE

- Rubber

- And Ceramic fiber

A list of materials that can be used for metallic gaskets is given in ASME B16.20. Some of the materials are

- Soft iron

- Low carbon steel

- 4-6% Chrome, ½ Mo

- Stainless steel Type 304,316,347,410

- Metallic gasket can be manufactured from Service specific material as suggested by the designer.

The only thing you have to take care of is that the hardness of the gasket shall always be less than the flange material by at least 50 BHN.

What will happen if the gasket hardness is more than the flange? When you tighten the flange, the gasket will damage the serration and will no longer hold the leak.

Winding and Outer Ring Materials Types

In a spiral wound gasket, Winding Strips are manufactured from

- Stainless steel material grades such as Type 304,316,347

- Or Exotic material such as Monel, titanium, or a duplex can also be used as per service requirements.

The filler material of the winding can be a Flexible Graphite or PTFE, depending on of service temperature of the gaskets. PTFE is not used for high-temperature services.

The Outer Ring of the Spiral Wound Gasket is mostly manufactured from Carbon steel, whereas the Inner ring is mostly manufactured from Stainless Steel Type 304, 316, 321, 347.

It can also be manufactured from exotic materials such as Monel, titanium, duplex, etc. These depend on the type of fluid inside the pipe as an inner ring is in direct contact with the fluid.

Dimensional Standards

Gasket dimensions are covered in the following standards.

- ASME B 16.20 -Metallic Gaskets for pipe flanges

- ASME B 16.21-Non-metallic Gaskets for pipe flanges.

Read Also

What are flanges and their types

What is piping used in oil and gas industry

Download free PDF Piping Interview question answer

36 thoughts on “Types of gaskets used in oil and gas industry PDF”