What are the internals in the distillation column PDF?

Introduction of Column Internals

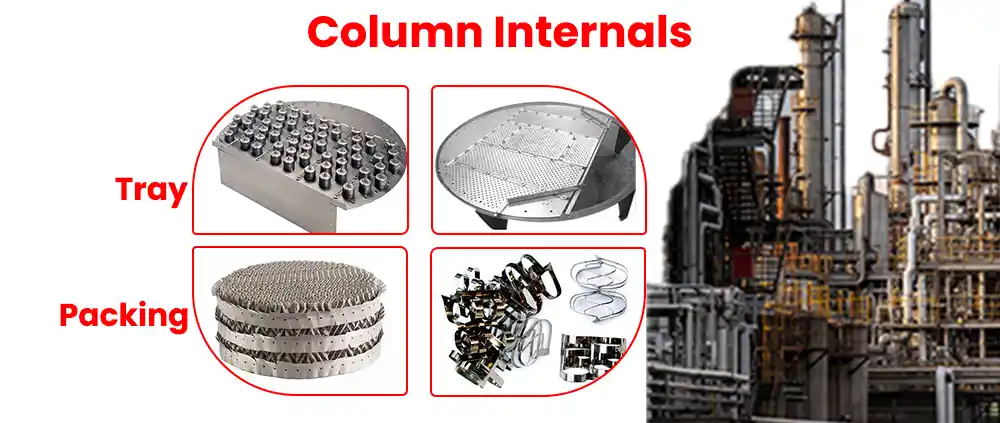

In this article, we will talk about the internal parts of the distillation column. The internals of the distillation column are the components that help to increase the contact between the liquid and vapor phase which makes it very easy to separate the liquid mixtures which have different boiling points.

Types of Column Internals

There are different types of column internals but mainly it is divided into two types: Trays and Packings, further trays and packings are also divided into different types which we will further in detail.

- Trays

- Packings

Trays

Trays are the main component of a distillation column which are similar to plates that are spaced evenly throughout the column. The vapor flows up through the holes or slots in the trays, while the liquid flows down through the downcomers which allows a mass transfer to occur between the two phases. The vapor and liquid are brought into contact with each other at the interface between the tray and the downcomer.

A tray consists of several parts like the bubbling area, the weir and the downcomer.

The bubbling area define the tray type and its operation. The weir fixes the liquid height and the pressure drop, the downcomer allows the transit of the liquid towards the lower plate and forces the steam through the bubbling area.

There are many different types of trays, each with its own advantages and disadvantages. Some common types of trays include:

Bubble Cap Trays: These trays have caps that fit over the holes in the tray. The caps create a small bubble of vapor that rises through the hole, mixing with the liquid below. The cap is mounted so that there is a space between riser and cap to allow the passage of vapor.

Sieve trays: These trays have holes or slots in the tray plate. The vapor flows up through the holes or slots, mixing with the liquid below.

Valve trays: These trays have valves that are opened and closed by the vapor flow. The valves control the amount of vapor that flows through the tray, which affects the efficiency of the separation.

Design of Tray

Each tray acts as a mini-column, and achieving a fraction of the separation. So we can say that the more trays there are, the better the degree of separation and that overall separation efficiency will depend significantly on the design of the tray. Trays are designed to maximize vapour-liquid contact by considering the

- liquid distribution and

- vapour distribution

on the tray. This is because better vapour-liquid contact means better separation at each tray, translating to better column performance. Less trays will be required to achieve the same degree of separation. Attendant benefits include less energy usage and lower construction costs.

Packing

Packings are randomly arranged or structured materials that are placed inside the column. The vapor and liquid flow through the packings, coming into contact with each other at the surface of the packings.

There are different types of packing available but mainly it is divided into two types.

- Structure Packing

- Random Packing

Structure packing: This is a type of packing which is known for its efficiency and low-pressure drop. It was proposed by Labbe and allows to decrease the size of columns compared to other distillation column internals. This packing consists of a set of corrugated sheets that are arranged in a honeycomb pattern.

The corrugated sheets create a large surface area for the liquid to contact, which improves the efficiency of the separation process. The low pressure drop means that less energy is required to move the fluids through the column, which can save money on operating costs.

Structured packing is made from a variety of materials, including metal (Stainless steel, Aluminum, Hastelloy, Inconel …), plastic (PS, PPH, HDPE, PVC, PVDF …), and ceramic. The choice of material depends on the specific application. For example, metal-structured packing is often used in harsh environments, while plastic-structured packing is more economical.

Structured packings are blocks of corrugated plates that are assembled back to back. The average height of each block is 270 mm. A liquid distributor is required at the top of the column to ensure that the liquid is evenly distributed over the packing. Redistributors are needed when the total packing height is greater than 4.5 meters. A support grid is also required to support the packing, and a hold-down grid can be installed to prevent the packing from moving.

- Liquid distributor: This is a device that ensures that the liquid is evenly distributed over the top of the structured packing. This is important for ensuring that the entire packing is wetted and that the separation process is efficient.

- Redistributor: This is a device that is used to distribute the liquid evenly over the packing when the total packing height is greater than 4.5 meters. This is necessary because the liquid tends to channel through the top of the packing, and a redistributor helps to spread the liquid out more evenly.

- Support grid: This is a device that supports the structured packing in the column. It is made of metal or plastic bars that are arranged in a grid pattern. The support grid prevents the structured packing from collapsing under the weight of the liquid and gas.

- Hold-down grid: This is a device that is installed on top of the structured packing to prevent it from moving. It is made of metal or plastic bars that are arranged in a grid pattern. The hold-down grid helps to keep the structured packing in place and prevents it from being dislodged by the liquid and gas flows.

Random packing: This is a type of packing material consisting of small, randomly arranged elements with different shapes. The elements are typically made of metal, plastic or ceramic, and they are available in a variety of shapes and sizes.

The mass transfer between the vapor and the liquid occurs at the surface of each element. The vapor flows through the voids between the elements, and the liquid flows over the surface of the elements. The contact between the vapor and the liquid at the surface of the elements allows for the transfer of mass between the two phases.

Random packing is a popular choice for distillation columns, absorption columns, and other separation processes. It is a relatively inexpensive option, and it is easy to install and maintain. However, it has a higher pressure drop than structured packing, which means that it requires more energy to operate.

Here are some of the advantages of random packing:

- Inexpensive

- Easy to install and maintain

- Wide range of available materials and sizes

- Can be used for a variety of separation processes

Here are some of the disadvantages of random packing:

- Higher pressure drop than structured packing

- Can be less efficient than structured packing

- Can be more difficult to clean than structured packing

The choice of internals for a distillation column depends on a number of factors, including the type of mixture being separated, the desired separation efficiency, the pressure drop that can be tolerated, and the cost of the internals.

Other Components

In addition to the trays and packings, there are a number of other components that may be found in a distillation column, such as:

- Reflux condenser: This is used to condense the vapor that flows out of the top of the column. The condensed liquid is then returned to the column, which helps to improve the separation efficiency.

- Reboiler: This is used to vaporize the liquid that flows down from the top of the column. The vaporized liquid is then returned to the column, which helps to maintain the flow of liquid through the column.

- Distributors: These are used to distribute the liquid evenly over the trays or packings.

- Collectors: These are used to collect the liquid that flows off the trays or packings.

Conclusion

The internals of a distillation column play an important role in the performance of the column. The right choice of internals can help to improve the separation efficiency, reduce the pressure drop, and lower the cost of operation.

Read Also

Download Free Piping PDF for Interview Preparation