Static Equipment Introduction

Static equipment in oil and gas industry (PDF)

List of static equipment in the oil and gas industry pdf

Whenever we talk about the oil and gas industry, especially refineries and petrochemicals then the main components of these industries are various types of equipment that are used to extract, process, and transport hydrocarbons efficiently and safely.

There are two types of equipment used in the oil and gas industry.

- Static Equipment

- Rotating Equipment

In this article, we are going to talk about static equipment which is one of the most important categories of equipment in the oil and gas industry. Static equipment is stationary, which means there are no moving components or parts available in the equipment. Static equipment plays an important role in the entire oil and gas industry.

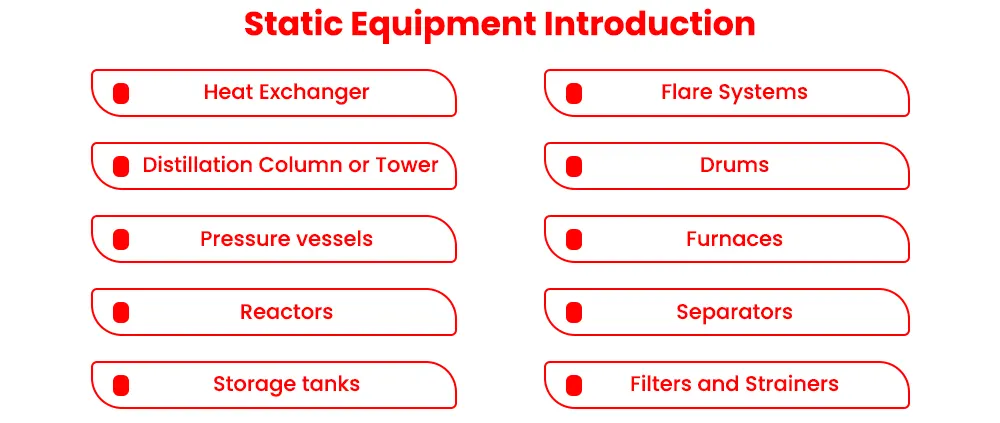

Types of Static Equipment

In this article, we will take a closer look at the different types of static equipment commonly used in the oil and gas industry. We will also discuss the functions and significance of each type of equipment.

1) Heat Exchanger- A heat exchanger is such equipment that can be found almost in every unit like- CDU, VDU, FCCU, Boiler, CFP, Bitumen, Utilities, etc. so Heat exchanger is a system used to transfer heat between two or more fluids. Heat exchangers are used in both heating and cooling processes as well as to condense steam, where fluids are separated by a solid wall to prevent mixing or they may be in direct contact.

2) Distillation Column or Tower- Distillation column or tower is an equipment which is used in the distillation of two or more liquid mixtures into its component parts or fractions based on differences in volatilities or their boiling points. Columns are tall and cylindrical vessels in shape and size that are used to separate fluids. They are used in a variety of applications in the oil and gas industry, including separating crude oil into its various components, such as gasoline, diesel, and jet fuels.

3) Pressure vessels– A pressure vessel is a container designed to hold liquid or gases at a pressure substantially different from the ambient pressure. They are used in a variety of applications in the oil and gas industry, including storing hydrocarbons, separating fluids, and reacting chemicals. They are essential components in refining, petrochemical, and production facilities, used for processes like separation, heat exchange, and storage. Pressure vessels come in various shapes and sizes, such as drums, tanks, and towers, and are constructed with materials capable of withstanding the extreme conditions present in the oil and gas environment.

4) Reactors– In oil and gas industry reactors are the heart of the industry. Reactors are like vessels designed for chemical reactions to take place under controlled conditions. In the oil and gas industry, reactors are used in processes such as catalytic cracking and hydrocracking, which are essential for converting crude oil into valuable products like gasoline and diesel.

5) Storage tanks– Storage tanks are used to store hydrocarbons and other fluids. They are an essential part of the oil and gas industry, as they allow companies to store large quantities of fluids for later use.

6) Flare Systems– Flare systems consist of stacks and associated equipment used for safely burning off unwanted gases during emergency or maintenance situations. Flares are a critical safety feature in the oil and gas industry, preventing the release of harmful emissions and reducing the risk of explosions.

7) Drums– Drums are cylindrical vessels used for a variety of purposes in the oil and gas industry, such as accumulating liquids or facilitating phase separation. They can be found in different stages of production and play a role in processes like condensation, dehydration, and settling.

8) Furnaces– Furnaces are heat-producing equipment used for various purposes, including crude oil heating, distillation, and thermal cracking. They play an important role in converting raw materials into valuable products through controlled heating processes.

9) Separators– Separators are vital in the oil and gas industry for separating oil, gas, and water from the well stream. They are used to remove impurities and ensure the produced fluids meet quality standards. Separators are designed with various internal components and configurations to achieve efficient phase separation, making them a key element in upstream operations.

10) Filters and Strainers– Filters and strainers are essential static equipment for removing particulates and contaminants from fluids, ensuring the quality and reliability of downstream processes. They are used in various stages of oil and gas production and processing to maintain the integrity of equipment and products.

11) Cooling Tower- A cooling tower in oil and gas industry is just like a heat exchanger that uses the evaporation of water to cool water that is used to cool equipment and processes in the refinery. The hot water is circulated through the cooling tower, where it is sprayed into a tower filled with air. The air evaporates some of the water, which carries away the heat. The cooled water is then returned to the refinery to be used again.

Cooling towers are essential for refineries because they help to conserve water and prevent the buildup of heat. Without cooling towers, the refinery would have to use a lot more water, and the heat buildup could damage equipment and create safety hazards.

Importance of Static Equipment

Static equipment plays an important role in the oil and gas industry. It is used to extract, process, and transport hydrocarbons safely and efficiently.

Here are some of the specific functions and significance of static equipment in the oil and gas industry:

- Storing hydrocarbons: Static equipment is used to store hydrocarbons. For example, pressure vessels are used to store fluids under pressure.

- Processing hydrocarbons: Static equipment is used to process hydrocarbons into usable products. For example, heat exchangers are used to cool or heat fluids, which helps to separate the different components of crude oil.

- Transporting hydrocarbons: Static equipment is used to transport hydrocarbons to their end users. For example, storage tanks are used to store large quantities of hydrocarbons, which can then be transported by pipelines or ships.

Conclusion

Static equipment is essential to the oil and gas industry. It is used to extract, process, and transport hydrocarbons safely and efficiently. Without static equipment, the oil and gas industry would not be able to function.

Read Also

Download Free Piping PDF for Interview Preparation