Introduction of Fittings

In the oil and gas industry, where safety, efficiency and reliability are most important.

These small, but essential components play a vital role in connecting and directing the flow of various fluids and chemicals in the extensive network of pipelines that form the backbone of this vital sector.

In this article, we will elaborate on the importance of piping fittings, their types and the very important role they play in ensuring uninterrupted operations within the oil and gas industry.

The Role Of Piping Fittings

Piping fittings serve as links between different sections of pipelines, as well as between pipelines and various equipment. They enable the redirection, connection, branching and termination of pipelines, ensuring the smooth and efficient flow of hydrocarbons. These fittings act as connectors, reducing the need for complex welding and fabrication, thereby saving time and cost during installation and maintenance.

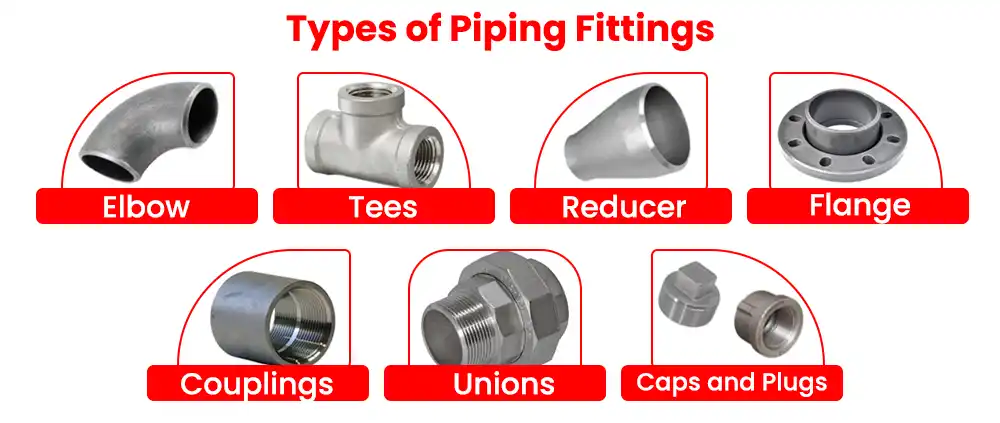

Types of Piping Fittings

Elbow:

Elbows are curved fittings that change the direction of a pipeline. Typically available in 45° and 90° variants, they are vital for navigating pipelines around obstacles and for changes of direction.

Tees:

Tees have a T-shaped design and are used to make branch connections, allowing fluid or gas to flow in two or more directions.

Reducer:

Reducers are used when the diameter of a pipe needs to be changed, either to accommodate changes in flow rate or to connect pipes of different sizes.

Flange:

Flanges are flat, circular discs with evenly spaced holes that facilitate connections between pipes, valves, and other equipment. They provide easy access for maintenance and repair.

Know more what are flanges and its types

Couplings:

Couplings are used to join two pipes of the same diameter together. They come in a variety of designs, including compression couplings, mechanical couplings, and welded couplings.

Unions:

Unions are similar to couplings but are more easily removable, making them ideal for applications that require frequent disconnections.

Caps and Plugs:

Caps and plugs serve to terminate the end of a pipeline, securely sealing it when not in use.

Materials and Standards

Given the challenging conditions in the oil and gas industry, piping fittings are manufactured from robust materials to ensure longevity, safety, and corrosion resistance. Common materials include carbon steel, stainless steel, alloy steel, and non-ferrous metals. Depending on the specific application and the fluid being transported, different materials are chosen to withstand high pressures, extreme temperatures, and corrosive environments.

It is essential to adhere to stringent industry standards during the manufacture and installation of piping fittings. Standards such as API 5L (Specification for Line Pipe), ASME B16.9 (Factory-Made Wrought Steel Butt-Welding Fittings), and ASTM A234 (Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Medium- and High-Temperature Service) provide guidelines for ensuring quality, safety, and compatibility with existing infrastructure.

Conclusion

In the oil and gas industry, where every aspect of operations must be carefully planned and executed, the importance of piping fittings cannot be overstated. These seemingly simple components play a vital role in maintaining the integrity and efficiency of the vast network of pipelines that transport hydrocarbons over long distances.

By providing secure connections, facilitating changes of direction and enabling smooth flow transitions, piping fittings contribute significantly to the safety and success of the oil and gas industry. As technology advances, we can expect more innovations in piping fittings to enhance their performance and contribute to the continued growth and stability of the industry.

Download Free Piping Question Answer PDF

What is gasket and their types

What is a valve and its types?

2 thoughts on “Types of pipe fittings in oil and gas industry Download 5 Free PDF”