Introduction of Vessel

Pressure vessels are types of containers designed to hold liquids, vapors, or gases. Examples of common pressure vessels used in the petroleum refining and chemical processing industries include but are not limited to, storage tanks, boilers, and heat exchangers.

Petroleum refineries are complex industrial facilities where crude oil is transformed through various refining processes into a range of valuable products. Vessels, a class of specialized equipment, play an important role in these purification operations, providing containment and facilitating essential chemical and physical processes. This article highlights the importance of vessels in refineries and explores the different types used in the pursuit of efficient and safe petroleum processing.

Role of Vessels in refineries

Vessels are closed containers used in refineries to hold and process crude oil and its derivatives during various stages of refining. These robust structures are designed to withstand high pressures and temperatures while ensuring safety and efficiency in refining operations. Vessels are important components in refining because they allow chemical reactions, separation, and storage of intermediate and final products.

ASME Section VIII is the section of the ASME Boiler and Pressure Vessel Code (BPVC) that covers pressure vessels. It gives detailed requirements for the design, manufacture, testing, inspection and certification of both fired and unfired pressure vessels.

API 510, “Pressure Vessel Inspection Code: In-Service Inspection, Rating, Repair, and Alteration” is an inspection code written and published by the American Petroleum Institute, which covers in-service inspection, repair, alteration, and rerating activities. For pressure vessels and the pressure relief devices protecting these vessels.

When it comes to inspection, most pressure vessels must be inspected once before being placed in service and re-inspected every 5 years after each change or major repair. An inspection may be internal, external or both and should include a thorough examination, thickness assessment, stress analysis, inspection of the vessel’s pressure release valve, and hydrostatic pressure testing. It is also important to inspect the surface, check insulation and any structural connections, and finally inspect any welds or joints.

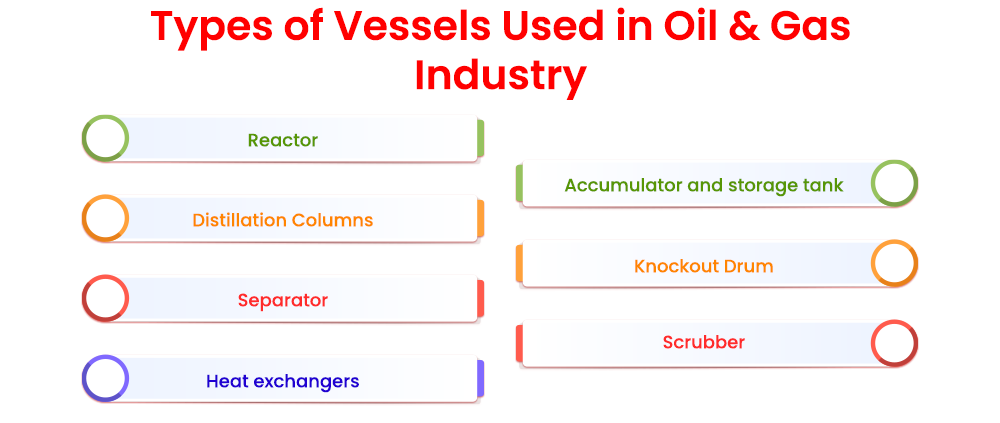

Types of Vessels Used in Refineries

Reactor

Reactors are vessels designed to contain and facilitate the chemical reactions that transform feedstock molecules into desired products.

In refineries, various types of reactors are used, such as catalytic reactors for processes such as hydrocracking, hydrotreating, and reforming. These vessels contain catalysts that facilitate reactions, increasing product yields and quality.

Distillation Columns (Fractionation Towers)

As discussed in the previous article, distillation columns are essential vessels that separate crude oil into various components based on their boiling points.

These tall vertical vessels provide the necessary surface area for vaporization and condensation of the various hydrocarbon fractions.

Separator

Separators are vessels used to separate different phases of hydrocarbons, such as liquid-liquid separators, liquid-gas separators, and three-phase separators.

These vessels aid in the separation of oil-water mixtures and gas-liquid mixtures, which are important in the production of clean fuels and petrochemical feedstocks.

Heat exchangers

Heat exchangers are vessels used to transfer heat between different process streams, thereby increasing energy efficiency in the refining process.

They are important for preheating the feedstock, cooling the products, and recovering heat from the various streams.

Accumulator and storage tank

Accumulators and storage tanks are large vessels used to store intermediate and final products during various stages of refining.

These vessels provide buffer capacity to ensure a continuous supply of products and smooth out variations in demand.

Knockout Drum

Knockout drums are vessels used to remove entrapped liquids from gas streams, ensuring that only the gas is further processed.

They help protect downstream equipment from potential damage from liquid carryover.

Scrubber

Scrubbers are vessels designed to remove impurities such as sulfur compounds and other pollutants from process gas streams.

They play a vital role in ensuring environmental compliance and clean emissions.

Conclusion

Finally, vessels are indispensable assets in petroleum refineries, enabling the safe and efficient transformation of crude oil into a variety of valuable products. From reactors that drive essential chemical reactions to distillation columns that fractionate crude oil, each type of vessel serves a specific purpose in the complex refining process.

These vessels contribute to the refinery’s overall productivity, safety, and environmental compliance, helping them meet the growing demand for clean and high-quality petroleum products. As technology advances, vessels will continue to evolve, further optimizing refining processes and making them even more sustainable for the future.

Read Also

Download Free Piping PDF for Interview Preparation

1 thought on “What are Vessels and Their Types Download 5 Free PDF”