Introduction of Safety

Safety in a oil and gas industry refers to the set of practices, protocols and measures taken to prevent accidents, protect workers and reduce the risk of occurrences that may cause injuries, death, environmental damage or loss of property .

Refineries are complex industrial facilities where crude oil is processed to produce various petroleum products, such as gasoline, diesel, jet fuel, and other petrochemicals. Due to the nature of their operations, refineries can present a number of hazards including fire, explosion, toxic emissions and process disturbances.

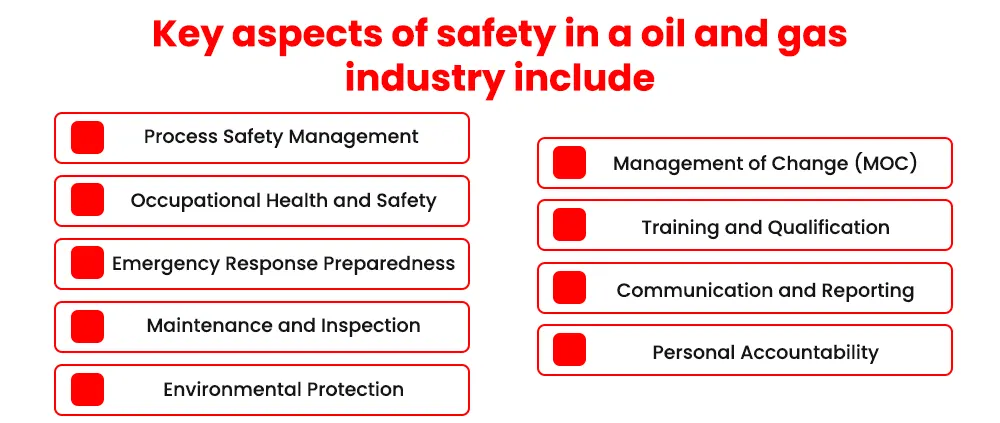

Key aspects of safety in a oil and gas industry include

Process Safety Management (PSM)

This involves a systematic approach to managing the integrity of a refinery’s processes and operations. This includes the identification, risk assessment, prevention and mitigation of potential incidents related to the handling of hazardous materials and high pressure systems.

Occupational Health and Safety

Refineries must maintain a safe working environment for their employees and contractors. This includes providing appropriate personal protective equipment (PPE), implementing safety training programs, conducting regular safety inspections, and promoting a safety culture among workers.

Emergency Response Preparedness

Refineries must have comprehensive emergency response plans in place to effectively handle incidents. These plans outline procedures for evacuation, fire fighting, leak containment and communication with relevant authorities.

Maintenance and Inspection

Regular maintenance and inspection of equipment, pipelines, and other critical infrastructure is necessary to identify potential issues before they become a safety hazard.

Environmental Protection

Refineries must follow environmental regulations to minimize their impact on the surrounding environment. This includes responsibly managing emissions, wastewater and waste disposal.

Management of Change (MOC)

Any change to a refinery’s processes, equipment or procedures must undergo a thorough assessment and approval to ensure that the safety implications are appropriately addressed.

Training and Qualification

Workers must receive adequate training to understand the potential hazards they may face and the safety measures they must follow.

Communication and Reporting

Clear communication channels and reporting systems help ensure that security concerns are addressed promptly, and lessons learned from incidents are shared throughout the organization to prevent similar incidents in the future .

Personal Accountability

Everyone within a refinery, from top management to frontline workers, shares responsibility for safety. Encouraging personal accountability for safety fosters a strong safety culture.

Safety in a refinery is a continuous endeavor that requires the commitment of all stakeholders to create a safe working environment and protect the community and the environment from potential risks associated with refinery operations.

Ensuring Safety During Oil and Gas Shutdown: Following Crucial Factors to be Considered

Oil and gas shutdowns are critical events that require careful planning and implementation to protect the environment, workforce and surrounding communities. Whether for routine maintenance, emergency situations or equipment repair, ensuring safety during shutdown is of utmost importance. In this article, we’ll explore the important factors and best practices for ensuring a smooth and safe oil and gas shutdown process.

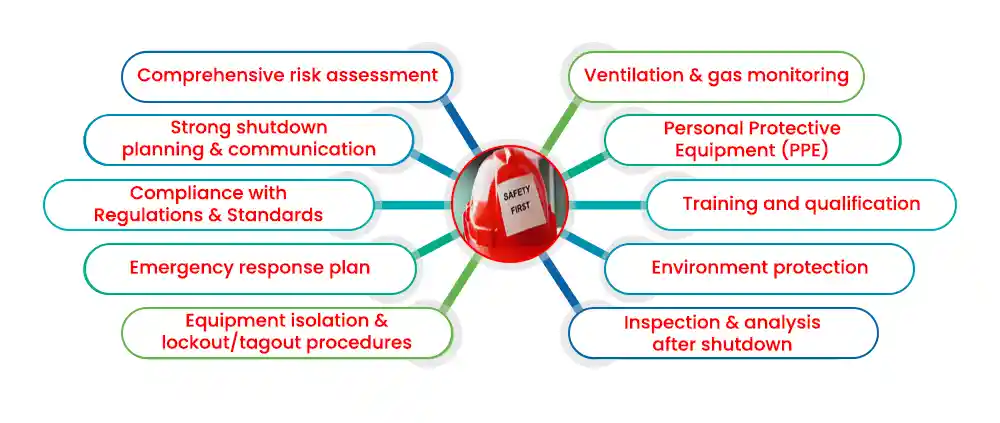

Comprehensive risk assessment

Prior to commencing any shutdown activity, a comprehensive risk assessment should be conducted. This assessment should identify potential hazards and risks associated with the shutdown, including equipment failure, leaks and other safety concerns. Analyzing vulnerabilities will help develop appropriate security measures and minimize potential accidents.

Strong shutdown planning and communication

A well-structured shutdown plan is the foundation of a safe and successful operation. The plan should outline the entire shutdown process, including timelines, roles and responsibilities of each team member involved. Effective communication between all stakeholders, from management to on-site workers, is critical to ensure that everyone understands procedures and safety protocols.

Compliance with Regulations and Standards

Adhering to safety regulations and industry standards is non-negotiable during an oil and gas shutdown. There are strict guidelines from national and international regulatory bodies that must be followed to prevent accidents, protect the environment, and maintain the overall integrity of the facility.

Emergency response plan

Even with careful planning, unforeseen events can occur during a shutdown. A well-defined emergency response plan is essential in order to swiftly and efficiently handle potential accidents. The plan should include evacuation procedures, communication protocols and medical support arrangements.

Equipment isolation and lockout/tagout procedures

Proper isolation of equipment and pipelines is important to prevent the release of hazardous materials during shutdown. Implementing lockout/tagout procedures ensures that machinery is safely shut down and cannot be accidentally restarted during maintenance, greatly reducing the risk of injury.

Ventilation and gas monitoring

In closed spaces or confined areas, proper ventilation is important to prevent the build-up of toxic or flammable gases. Continuous monitoring of gas levels during the shutdown process helps identify potential leaks and unsafe conditions, allowing for timely intervention.

Personal Protective Equipment (PPE)

Providing appropriate personal protective equipment (PPE) to all workers is essential to safeguarding their health and well-being. Depending on the identified hazards, workers should be equipped with safety goggles, gloves, hard hats, fire-resistant clothing, and respirators to protect them from potential exposures.

Training and qualification

Ensuring that all personnel involved in shutdown receive adequate training is a fundamental aspect of maintaining safety. Workers must be well-versed in safety protocols, equipment management, and emergency procedures. Regular competency assessments can help identify areas that require additional training.

Environment protection

Oil and gas fracking can pose a risk to the environment, especially in the event of a leak or spill. Implementing environmental protection measures, such as containment booms and spill response equipment, can help prevent or minimize environmental damage during shutdowns.

Inspection and analysis after shutdown

Once shutdown is complete, a thorough inspection should be made to ensure that all safety measures have been diligently followed. Any issue found during inspection should be resolved immediately to prevent recurrence of shutdown in future. Post-shutdown analysis helps identify areas for improvement and refine safety protocols.

Conclusion

Ensuring safety during an oil and gas shutdown requires a proactive approach. By conducting a risk assessment, complying with regulations, promoting effective communication and providing appropriate training and equipment, companies can significantly reduce the likelihood of accidents and protect their workforce, the environment and their reputation.

With every shutdown, there are opportunities to learn and enhance safety practices, fostering a culture of safety that extends beyond the shutdown and into daily operations. Ultimately, prioritizing safety is not only a moral obligation but also a strategic investment that leads to operational efficiency and sustainable success in the oil and gas industry.

Read Also

Download Free Piping PDF for Interview Preparation

Sir I want LOTO procedures. Please upload full details of LOTO Procedures. My Whatsapp number is 00966580753895.