Flanges Introduction:

Flanges play an important role in the oil and gas industry, serving as essential components connecting pipes, valves, and other equipment. These circular or square plates with a hole in their center facilitate easy connection and separation of various piping systems, allowing for efficient maintenance and repair procedures. In this article, we will explore the different types of flanges and their diverse applications within the oil and gas sector.

Type of Flanges

Weld Neck Flange

Weld neck flanges are most popular in critical applications where high pressure and temperature conditions are applicable. They have a long tapered hub that gradually tapers into the outer diameter of the pipe. Weld neck design provides excellent reinforcement and minimizes the risk of leakage. These flanges are most commonly used on the ends of pipelines and heat exchangers. You can easily recognize these types of flange after seeing this.

Slip-on Flange

Slip-on flanges are easy to install and are simply slipped over the end of the pipe before it is welded. Although they are not suitable for high-pressure systems, they are cost-effective and ideal for low-pressure applications where frequent dismantling is not required.

Socket Weld Flange

The socket weld flange has a socket-like end where the pipe is inserted for welding. They are suitable for small-diameter pipes and are commonly used in systems with high pressure and temperature requirements.

Blind Flange

Blind flanges, also known as blanking flanges, are used to close off the end of a piping system. They have no center hole, which makes them effective for clogging pipes or vessels. Blind flanges are often used in pressure testing and maintenance procedures.

Threaded Flange

Threaded flanges have internal threads and are attached to pipes with external threads. They are popular for low-pressure applications and can be easily assembled and disassembled, making them suitable for installations where frequent maintenance is necessary.

Lap Joint Flange

The lap joint flange consists of two components: the flange itself and a separate stub end. Both parts are aligned and connected using bolts. These flanges are beneficial when alignment adjustments are required during assembly.

What is SMAW Welding Know More about it?

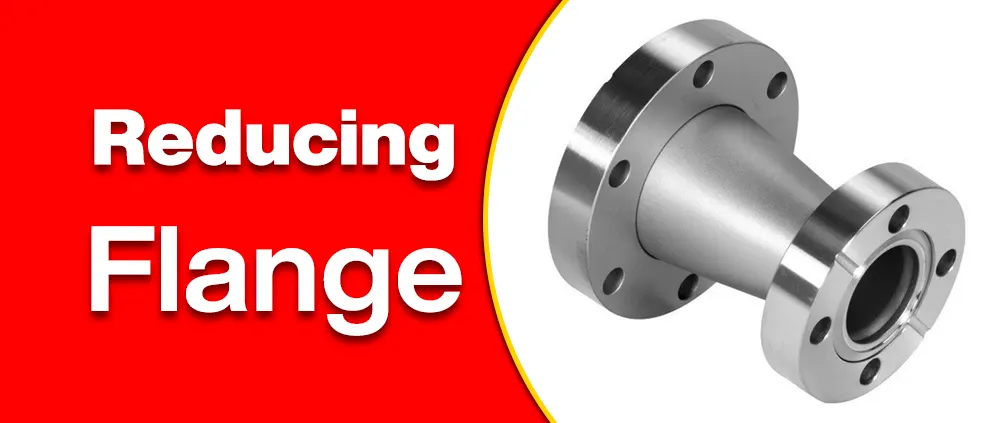

Reducing Flange

The reducing flanges are used to connect between larger and smaller sizes without using a reducer. In the case of reducing flanges, the thickness of the flange should be that of the higher diameter.

Integral Flange

Integral flanges are those, which are cast along with the piping component or equipment.

Use of Flanges in oil and gas industry

- Exploration and Production (Upstream): In the upstream sector, flanges are used in wellheads, Christmas trees, and flowlines. Weld neck flanges are commonly employed on high-pressure wellhead connections, ensuring reliable and leak-free operation. Blind flanges are used during well testing, and slip-on flanges are preferred for low-pressure flowlines.

- Transportation (Midstream): In midstream activities, flanges are used extensively in pipelines to transport oil and gas from production areas to processing facilities and ultimately to storage or distribution points. Weld neck flanges are used on pump and compressor stations due to their high pressure capabilities.

- Refining and Processing (Downstream): Various applications of flanges are involved in downstream processes such as refining crude oil and processing natural gas. Blind flanges are used to isolate equipment during maintenance, while slip-on flanges are used in low-pressure applications such as connecting distillation columns.

- Distribution and Storage (Downstream): In the downstream sector, flanges are integral in connecting storage tanks, loading and unloading terminals and distribution facilities. Threaded flanges are often used in low pressure gas distribution systems, ensuring ease of maintenance.

- Offshore Platform: Flanges are important components in offshore platforms, where they connect various piping and equipment. Due to the harsh marine environment, corrosion resistant materials and weld neck flanges are typically used to ensure the integrity of the connection.

Conclusion

Flanges are essential components in the oil and gas industry, enabling the safe and efficient operation of pipelines, valves, and other equipment. Their different types meet a wide range of applications, from high pressure upstream operations to low pressure downstream processes. Proper selection, installation and maintenance of flanges is critical to ensuring the integrity and reliability of the entire oil and gas infrastructure.

Download free PDF for Piping Interview Question Answer

Read Also

https://pipingpdf.in/what-is-valve-and-its-types-download-free-pdf/

https://pipingpdf.in/lifeline-of-the-oil-gas-industry-in-2023/

2 thoughts on “What is flange and types of flanges? Download 5 Free PDF”