uPVC Pipes, or un-plasticized polyvinyl chloride pipes, are highly durable, cost-effective, and versatile material widely used in various applications, from plumbing to window frames. In this comprehensive guide, we will explore uPVC pipes, their benefits, applications, pricing, and why they have become the material of choice for many industries.

What are uPVC Pipes?

uPVC pipes are made from un-plasticized polyvinyl chloride, a rigid form of PVC that doesn’t contain plasticizers, making it highly durable and resistant to corrosion. This unique material is known for its chemical resistance, making it an excellent option for transporting water, sewage, and other fluids.

Unlike traditional plastic pipes, uPVC pipes are designed to last longer and withstand extreme environmental conditions. They are non-toxic, lead-free, and environmentally friendly, which has contributed to their widespread use in both residential and industrial settings.

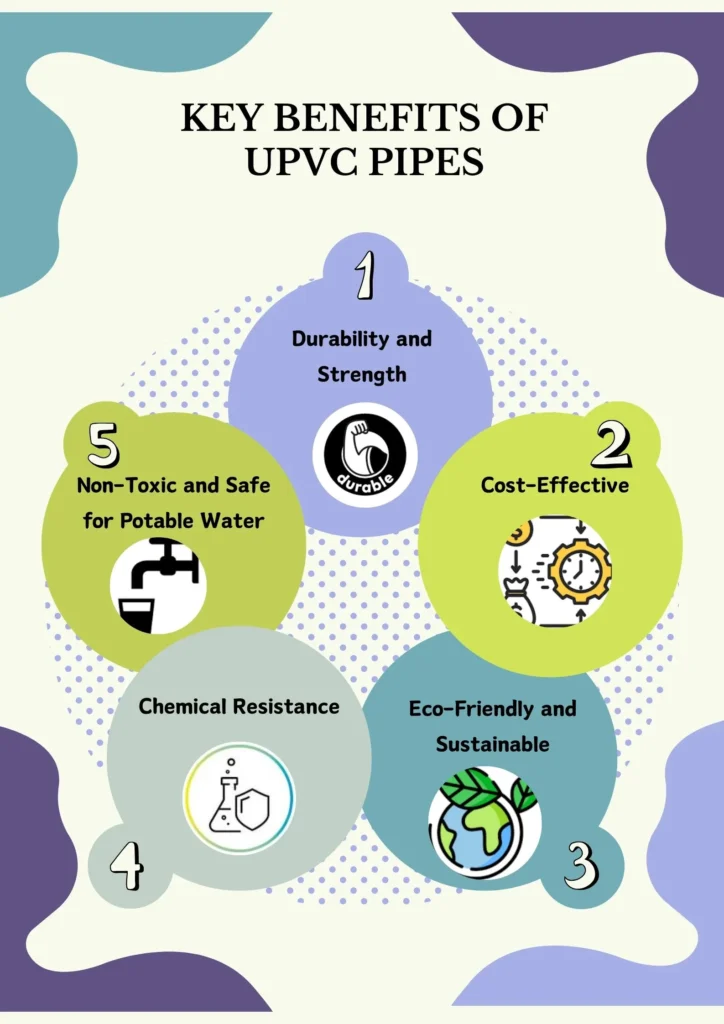

Key Benefits of uPVC Pipes

1. Durability and Strength

One of the most significant advantages of uPVC pipes is their long-lasting durability. uPVC is resistant to various environmental factors such as UV rays, chemicals, and physical wear and tear. This makes it ideal for outdoor applications, where the pipes may be exposed to harsh weather conditions.

2. Cost-Effective

Compared to other piping materials like copper or steel, uPVC pipes are highly cost-effective. Their production is less expensive, and their lightweight nature reduces transportation and installation costs. Furthermore, the low maintenance requirements of uPVC pipes result in long-term savings, making them an attractive choice for budget-conscious projects.

3. Eco-Friendly and Sustainable

uPVC pipes are considered more environmentally friendly than other types of plastic pipes because they are made from sustainable resources and can be recycled. Additionally, since uPVC pipes last longer, they contribute less waste to landfills over time. Their energy-efficient production process also makes them a greener option compared to traditional materials.

4. Chemical Resistance

The chemical resistance of uPVC pipes is one of their standout features. They can handle a variety of chemicals, including acids, alkalis, and salts, without degrading over time. This property makes them ideal for use in industrial applications, where harsh chemicals may be present in the transported fluids.

5. Non-Toxic and Safe for Potable Water

uPVC pipes are lead-free and non-toxic, which means they do not leach harmful chemicals into water or fluids. This makes them safe for potable water systems, ensuring that the water supply remains clean and uncontaminated.

6. Lightweight and Easy to Install

uPVC pipes are lightweight, which makes them easy to handle and install, reducing labor costs and time spent on installation. Their lightweight nature also makes them easier to transport, further reducing overall project costs.

Applications of uPVC Pipes

uPVC pipes are used in a wide variety of industries and applications, thanks to their versatility and durability. Some of the most common uses include:

1. Plumbing Systems

One of the primary applications of uPVC pipes is in plumbing systems. Their durability and resistance to corrosion make them ideal for both hot and cold water supply systems. Additionally, their smooth interior surface reduces friction, allowing water to flow more efficiently.

2. Irrigation Systems

uPVC pipes are widely used in agricultural irrigation systems due to their chemical resistance and strength. They can transport water, fertilizers, and other chemicals without reacting to the contents or deteriorating over time, ensuring a long lifespan for irrigation projects.

3. Drainage and Sewage Systems

The ability of uPVC pipes to resist harsh chemicals and prevent blockages makes them suitable for sewage and drainage systems. Their smooth surface ensures that waste and debris flow easily through the pipes, minimizing the risk of clogs or backups.

4. Industrial Applications

uPVC pipes are commonly used in industries that require the transportation of chemicals, gases, or liquids. Their resistance to chemical reactions makes them ideal for chemical plants, pharmaceutical factories, and other industrial environments.

5. Electrical Conduits

In the construction industry, uPVC pipes are often used as electrical conduits to protect wiring from environmental hazards. Their insulating properties and fire resistance make them a safe choice for this application.

Types of uPVC Pipes

There are various types of uPVC pipes designed for specific applications, each offering unique benefits. Some of the common types include:

1. uPVC Pressure Pipes

uPVC pressure pipes are used for applications where fluids need to be transported under high pressure, such as water supply systems or irrigation. These pipes are designed to withstand significant pressure without leaking or bursting.

2. uPVC Sewer and Drainage Pipes

These pipes are specifically designed for sewage and drainage systems, where they are exposed to harsh chemicals and physical wear. Their smooth surface prevents clogs, while their resistance to corrosion ensures a long-lasting performance.

3. uPVC Electrical Conduits

uPVC pipes used for electrical wiring protection are typically thinner and more flexible than other types of uPVC pipes. They provide a protective barrier for electrical cables, ensuring safety and durability in construction projects.

4. uPVC Plumbing Pipes

These pipes are designed specifically for use in residential and commercial plumbing systems. They are available in various sizes and diameters to accommodate different water flow requirements.

Pricing of uPVC and PVC Pipes

The pricing of uPVC and PVC pipes varies depending on the size, length, and specific application. Below are some general price ranges based on current market conditions, Please verify once before purchasing:

Price of 2 Inch uPVC Pipe (20 ft)

A standard 2-inch uPVC pipe (20 ft) typically costs between $15 to $30. Prices can vary depending on the brand, region, and specific supplier. These pipes are widely used for plumbing and irrigation purposes, making them a popular choice for homeowners and contractors.

Price of 50 mm uPVC Pipe

For a 50 mm uPVC pipe, the cost generally ranges from $10 to $25 per 20 ft length, depending on factors such as quality, brand, and local market conditions. These pipes are frequently used in plumbing and industrial applications.

Cost of PVC Pipe per Meter

The cost of PVC pipes is often calculated per meter. On average, PVC pipes can range from $1 to $3 per meter, depending on the diameter and pressure rating. Larger diameters or high-pressure pipes tend to be more expensive.

Price of 110 mm PVC Pipe (10 ft)

A 110 mm PVC pipe with a length of 10 feet typically costs between $20 to $40, depending on the manufacturer and region. These pipes are commonly used for drainage systems and sewer lines, where larger diameters are required for optimal flow.

Installation Tips for uPVC Pipes

When installing uPVC pipes, it’s essential to follow a few guidelines to ensure optimal performance and longevity:

1. Use the Correct Adhesive

Ensure that you use an appropriate adhesive when connecting uPVC pipes. The adhesive should be designed specifically for uPVC to create a strong, leak-proof bond between pipe sections.

2. Avoid Excessive Force

While uPVC pipes are durable, they can crack or become damaged if excessive force is applied during installation. Handle the pipes carefully and use appropriate tools to cut and fit them.

3. Check for Proper Alignment

When installing uPVC pipes, make sure the sections are aligned properly to avoid leaks or pressure imbalances. Misaligned pipes can lead to blockages or reduced efficiency.

4. Protect from UV Exposure

If uPVC pipes are installed outdoors, it’s important to shield them from prolonged exposure to direct sunlight, as UV rays can degrade the material over time. Consider using a UV-resistant coating or burying the pipes underground to protect them.

Why Choose uPVC Pipes Over Other Materials?

uPVC pipes offer numerous advantages over other traditional materials like copper, steel, or clay. Their cost-effectiveness, durability, and chemical resistance make them a superior choice for many applications. Additionally, their non-toxic nature ensures safety in potable water systems, while their easy installation and low maintenance make them ideal for large-scale projects.

In summary, uPVC pipes provide an all-around solution for a variety of needs, from plumbing and drainage to industrial and agricultural applications. Their long lifespan, affordability, and eco-friendliness continue to drive their popularity across multiple sectors.

How to Read P&ID A Complete Guide for Beginners. Click on the below link to Download PDF Now

Read Also

Download Free Piping PDF for Interview Preparation

Download Free Piping PDF for Interview Preparation

What is gasket and their types

What is a valve and its types?