Permit To Work (PTW) System: The Complete Guide

The Permit to Work (PTW) System is one of the most important safety systems used in hazardous industries like refineries, oil & gas, chemicals, and large construction sites. It helps control who can do what in restricted areas, making sure work is safe and well-managed. This article explains PTW in simple terms, with definitions, examples, and practical interview tips for anyone seeking to work as a permit receiver.

What is a Permit-To-Work System?

A Permit-to-Work system is a written safety authorization procedure/document. It gives official permission for performing work—such as construction, repairs, inspection, or maintenance—in places with higher risks, like where flammable or dangerous chemicals are handled, or where special hazards exist. PTW acts like a “safety contract” between all parties involved in hazardous work.

Example:

Before repairing a pump containing oil, workers must get a signed work permit from qualified officials, proving all hazards have been identified and controls are in place.

Why Do We Need a PTW System?

The PTW system aims to stop accidents before they happen. It demands proper planning, hazard assessment, and risk controls for jobs that could harm people, property, or the environment. Most importantly, it makes sure everyone—the employer, manager, supervisor, and worker—knows their responsibilities.

Example:

Welding in the refinery without a hot work permit could lead to fire or explosion. The PTW system would prevent this by demanding prior hazard checks and precautions.

Definitions You Must Know

Let’s go through the main PTW terms, explained simply:

Work Permit: A written document giving permission to perform a specific job at a specific time and place. It explains hazards, safety measures, and responsibilities.

Restricted Area: Any part of a site containing dangerous chemicals, heavy machinery/equipment, or processes. Such areas need permits for most work.

Permit Issuer: A certified official who checks risks and gives approval for work to begin.

Permit Receiver: The person (often from a contractor or maintenance team) certified to receive a work permit and execute the work safely.

Joint Inspection: A job site survey by both issuer and receiver, making sure all safety conditions are met before starting work.

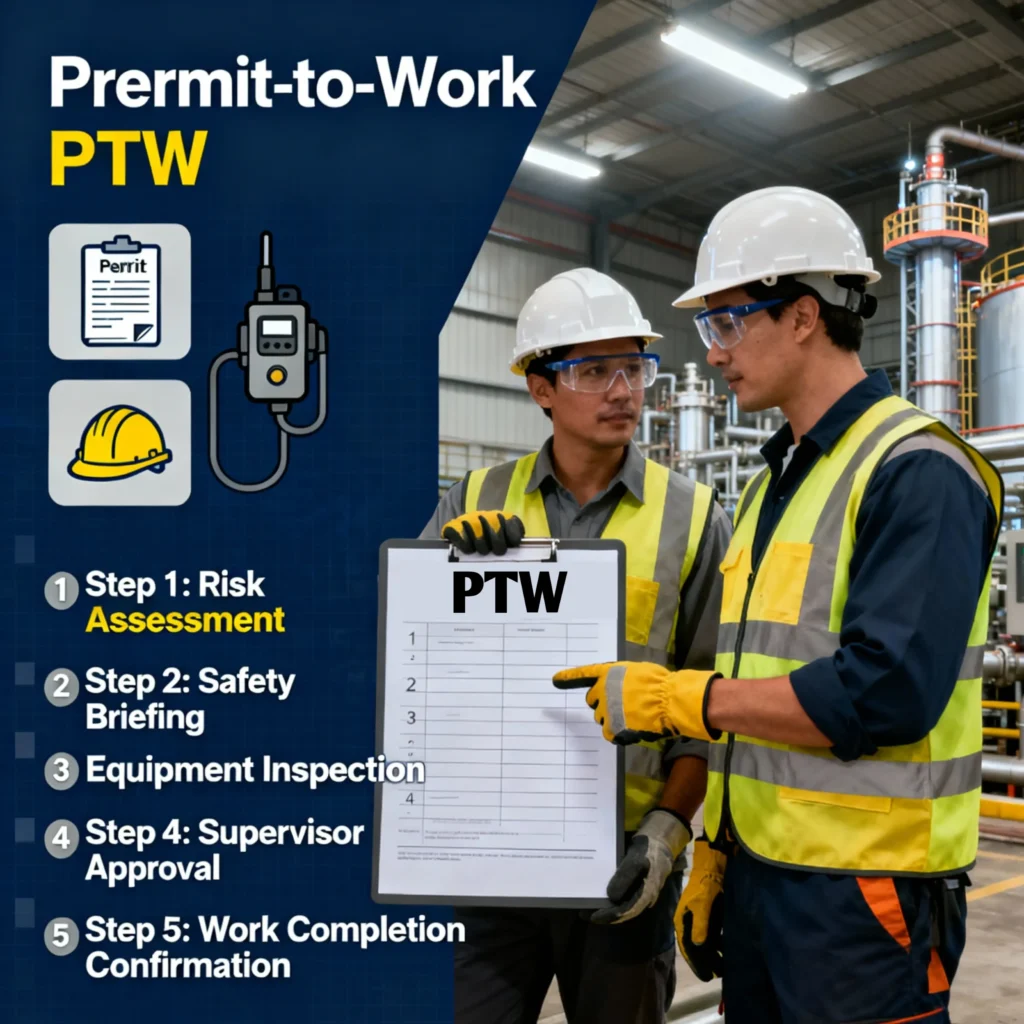

How Does the PTW System Work? Step-by-Step Process

1. Job Identification: Any high-risk activity is identified and classified.

2. Hazard Assessment: The hazards and risks are listed and analyzed – such as fire risk, gas leaks, or electrical shock.

3. Permit Issuance: The permit issuer fills out a written permit, detailing work, hazards, location, time, and safety precautions.

4. Site Preparation: The work area is made safe—may involve gas testing, equipment isolation, or setting up barriers.

5. Joint Inspection: Both issuer and receiver inspect the site together, checking if all conditions are satisfied.

6. Work Execution: The job is performed strictly as per permit instructions, with the receiver monitoring for safety.

7. Ongoing Checks: Safety checks and monitoring happen during the job, and if conditions change, work is stopped until reassessed.

8. Permit Closure: Once work is done, the site is inspected again. If safe, the permit is signed closed and records are kept.

Download Permit to Work PDF

Types of Work Permits

There are various permits, each for specific jobs, color-coded for easy recognition:

Hot Work Permit (Red): For jobs like welding, cutting, or anything creating sparks or heat. Strictly avoids fire risks.

Cold Work Permit (Blue): For non-hot work but still hazardous, such as Blinding & De-blinding, Housekeeping, mechanical repairs or chemical handling.

Confined Space Entry Permit/Authorization: Needed for entering tanks, pits, column, vessels, which may have low oxygen or toxic gases.

Electrical Isolation Permit: Ensures machines are de-energized for repairs, preventing electric shock.

Excavation Permit: For digging, trenching – checks for buried cables, gas lines, or collapse risk.

Lifting Permit: For crane work, lifting heavy loads, mandates stability and rigging checks.

Work at Height Permit: For working above ground (1.8 meter from ground), on scaffolds or ladders—prevents falls.

Equipment Opening/Line Breaking Permit: For disconnecting pipes or equipment carrying hazardous fluids or pressure.

Release of Hazardous Liquids/Gases Permit: Ensures proper control and containment when there’s risk of leaks.

Practical Example:

When you need to weld a pipeline, you require both a hot work permit and possibly a confined space permit if the job is inside a tank.

What Jobs Need a PTW? Work Examples

Welding, grinding, or cutting metal pipes in hydrocarbon areas.

Repairing electrical panels in hazardous locations.

Entering tanks for cleaning or inspection.

Digging trenches where underground utilities could be damaged.

Lifting heavy machinery using cranes.

Opening valves or lines previously used for chemicals.

Any job involving hazardous materials, explosives or radioactive substances.

Routine work in non-hazardous areas, like basic cleaning or photography not involving chemicals, often doesn’t need a permit but still requires some control.

Safety Controls and Hazard Management

Every PTW requires specific safety measures or controls to be put in place before work starts.

Atmospheric Testing: Checking for oxygen levels and flammable/toxic gases using approved detectors.

Isolation: Locking out and tagging equipment to prevent accidental activation.

Barriers & Signs: Setting up barricades and warning signs at sites.

Fire Watch: Designated personnel watching for fire hazards during hot work.

PPE (Personal Protective Equipment): Helmets, gloves, masks or breathing gear, especially in confined spaces.

Emergency Response Plans: Having clear instructions for evacuation, alarms, and rescue procedures.

Permit Validity and Extension Process

Permits are given only for the time required to finish a job. If work needs more time (for example, multi-shift repairs), extended permits can be issued but must be closely monitored and re-checked regularly.

Extended Permit: For jobs longer than two shifts (up to 30 days); includes daily checkpoints.

Renewed Permit: Allows work to continue next shift; max limit usually 24 hours.

Records of every permit must be kept for at least three months for auditing and investigation purposes.

Suspension and Closure of Permits

Work must be immediately stopped, and the permit suspended if:

There’s an emergency alarm.

Work plans change significantly.

Spare parts or materials are delayed.

Safety conditions on site change, introducing new risks.

After work finishes or the permit expires, both issuer and receiver inspect the site and formally close the permit, signing it. If work is not fully finished, new permits are issued for remaining tasks, following all checks.

Training and Competence: The PTW Foundation

Effective PTW depends on everyone being trained and competent. Training happens on-site, in classrooms, in small groups, and even through computer learning modules. Key training includes:

Understanding different types of permits.

Recognizing site hazards.

Learning about safety precautions and emergency plans.

Role-playing real permit scenarios.

Reviewing lessons learned from previous incidents.

All new employees and contractors must complete induction and permit training before working under the PTW system. Regular refresher courses ensure everyone stays up to date.

Interview Preparation Tips for Permit Receivers

If you’re preparing for a permit receiver interview in the oil and gas sector, follow these steps:

Learn Definitions: Clearly explain terms like hot work, confined space, and risk assessment.

Describe the PTW Process: Walk through each step in the permit cycle (from job identification to closure).

Show Hazard Awareness: Give examples of risks in specific jobs (like welding near tank farms).

Emphasize Responsibility: State how the receiver must follow all conditions—never take shortcuts.

Talk About Joint Inspections: Stress the importance of inspecting the work site with the issuer every time.

Mention Safety Controls: Be ready to speak about gas testing, isolations, using proper PPE, and emergency response.

Demonstrate Knowledge of Suspension: Explain when to stop work and how to safely resume.

Explain Training Needs: Note that every permit receiver must pass training before working.

Give Real-Life Examples: Share any work experience or training exercises related to PTW (even hypothetical ones).

Simple Scenario: Electrician Permit Receiver

Imagine an electrician arriving to repair a motor in a refinery:

1. Checks whether the job is in a restricted area and needs a permit.

2. Receives a permit from the issuer after joint hazard assessment and site inspection.

3. Confirms lockout/tagout procedures have made equipment safe.

4. Stays on site monitoring work safety and ready to stop work if a problem appears.

5. After finishing, joins with the issuer for a final inspection and permit closure.

6. Documents signed and stored for future audit.

Additional Advice for Students and Freshers

Always ask questions if you do not understand any part of the PTW form or process.

Never rush through site checks or safety briefings—attention to detail saves lives.

Build good communication skills. Brief your team on all hazards and controls before starting work.

Take training seriously—learning from past accidents and mistakes is vital.

Demonstrate positive safety attitude in interviews; show you care about team safety as much as your own.

Keep up with latest updates to PTW guidelines, as procedures can evolve with new technology and standards.

Permit-to-Work (PTW) System Interview Questions and Answers

1. What is the Permit-to-Work (PTW) system?

Ans- The PTW system is a formal safety control process used to manage hazardous work. It ensures that all high-risk jobs are authorized, hazards identified, and safety measures implemented before work begins.

2. Why is the PTW system important in refineries or oil and gas plants?

Ans- It prevents accidents by verifying that dangerous tasks like hot work, confined space entry, or electrical repair are performed under controlled and approved conditions.

3. Who issues a work permit?

Ans- A trained and authorized person, called the permit issuer, reviews the job details, checks safety precautions, and signs the permit to authorize the work.

4. Who is a permit receiver?

Ans- A competent employee or contractor responsible for executing the job safely after receiving the permit, understanding its conditions, and ensuring compliance.

5. What is joint site inspection?

It is a survey carried out by both the permit issuer and the permit receiver to verify that the worksite conditions are safe and all specified precautions are in place before starting.

6. What are the main objectives of the PTW system?

- Identify and control hazards

- Ensure safe coordination between departments

- Prevent unauthorized work

- Establish clear accountability for safety

7. What are the key stages in the PTW process?

Ans- Job identification, hazard assessment, permit preparation, site preparation, joint inspection, work execution, ongoing monitoring, and permit closure.

8. What is hot work permit?

Ans- A hot work permit authorizes tasks generating heat, flame, or sparks such as welding or cutting, ensuring fire prevention measures are in place.

9. What is cold work permit?

Ans- It covers work that does not involve heat or flame but could still be hazardous, such as mechanical maintenance or chemical cleaning.

10. What is confined space entry permit?

Ans- It allows trained personnel to enter enclosed spaces like columns, tanks or vessels after gas test, verifying atmospheric safety, isolation, and rescue arrangements.

11. What is electrical work permit?

Ans- It is a permit that ensures electrical systems are properly isolated and de-energized before maintenance to prevent electric shocks or short circuits.

12. What is an excavation permit?

Ans- This permit ensures safety when digging or trenching to avoid damage to underground (1.2 meter) utilities such as cables or pipelines.

13. What documents support the PTW?

Ans- Risk assessment sheets, job safety analysis (JSA), isolation certificates, gas test reports, and equipment checklist records are attached to the permit.

14. What is a gas test?

Ans- A gas test checks oxygen levels, flammable gases, or toxic substances using approved detectors before and during work, ensuring safe atmospheric conditions.

15. Who conducts gas testing?

Ans- A trained gas tester or authorized safety officer conducts and records gas test readings on the permit form before allowing work to proceed.

16. What are the typical validity periods for permits?

Ans- Work permits are usually valid for one shift (about 8–12 hours) and must be revalidated or renewed if work continues beyond the initial period.

17. What happens if the job is not completed within the permit duration?

Ans- The permit must be closed at the end of the shift, and a new permit issued after re-inspection and re-evaluation to ensure conditions remain safe.

18. What is permit suspension?

Ans- Permits are suspended when work must be temporarily stopped because of unsafe conditions, equipment failure, emergencies, or change in job scope.

19. When must a permit be cancelled?

Ans- A permit is cancelled after job completion, unsafe conditions, emergency shutdowns, or when work scope changes completely.

20. What are the main responsibilities of a permit issuer?

- Verify risk assessments

- Ensure correct permit type

- Inspect the site before issue

- Explain safety measures and controls

- Monitor ongoing work and close permit properly

21. What are the main responsibilities of a permit receiver?

- Understand permit conditions

- Ensure safety controls are followed

- Supervise team activities

- Stop work if unsafe conditions occur

- Inform issuer of job completion or issues

22. Why is isolation important in the PTW system?

Ans- Isolation prevents accidental release of energy or hazardous material. It safeguards workers by separating equipment from power, pressure, or chemicals before maintenance.

23. What is the difference between lockout and tagout?

Ans- Lockout physically prevents operation by locking switches or valves, while tagout provides a warning label showing equipment should not be used until safe.

24. What is simultaneous operation (SIMOPS)?

Ans- SIMOPS occurs when multiple activities happen in the same area. Proper PTW coordination ensures that one job does not create hazards for another.

25. What is a toolbox talk, and why is it linked to PTW?

Ans- A toolbox talk is a short briefing before starting work. It explains hazards, precautions, and permit conditions to ensure all team members understand the safety plan.

26. What are the color codes used for different permits?

Usually:

- Red – Hot Work

- Blue/Green – Cold Work

- Yellow – Confined Space

- White – Electrical Work

- Brown – Excavation

- Note: These colors can vary by company but help easily identify permit types.

27. What should you do if conditions at the site change after starting work?

Ans- Stop work immediately, inform the permit issuer, reassess risks, and revalidate the permit before resuming.

28. Why is record keeping important in PTW?

Ans- Permit records are used for safety audits, investigations, legal compliance, and continuous improvement in work safety processes.

29. What training is needed for workers under PTW?

Ans- All workers must complete PTW awareness, hazard identification, confined space entry, and emergency response training before participating in permitted work.

30. What is the final step after completing a job under PTW?

Ans- Conduct a joint site inspection, ensure equipment is safe for operation, clear tools and materials, close the permit, and sign off officially for recordkeeping.

Equipment of Oil & Gas Industry

- List of Static equipment in Oil & Gas

- Exchanger Maintenance Procedure

- Vessel Maintenance Procedure

- Distillation Column Maintenance Procedure