What are the centrifugal pumps?

Centrifugal pumps are the most common type of pumps used in a variety of applications including water supply, sewage treatment, industrial processes, and irrigation. They work by converting rotational energy from an electric motor or engine into the kinetic energy of the fluid being pumped.

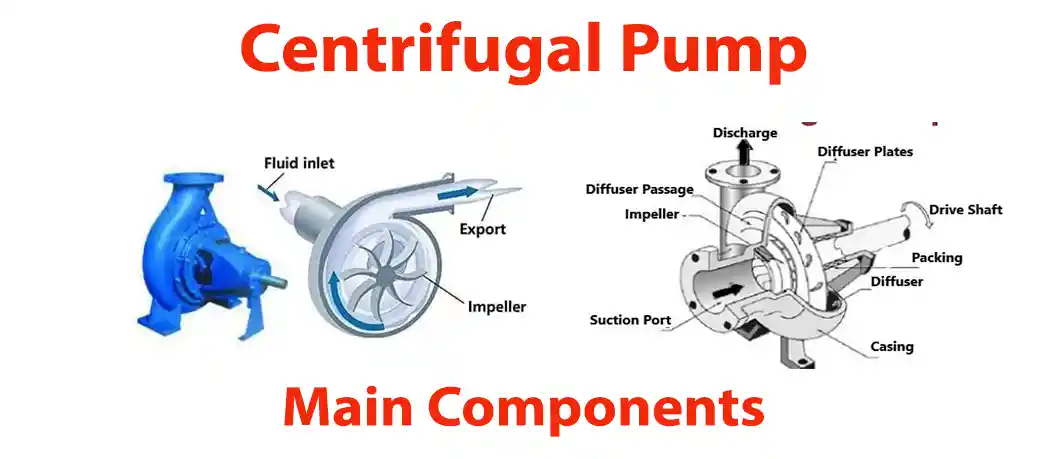

What are the main components of centrifugal pumps?

The main components of a centrifugal pump are:

- Impeller: A rotating wheel with vanes that accelerate the fluid.

- Casing or diffuser: A housing that contains the impeller and directs the flow of the fluid.

- Shaft: A rotating shaft that connects the impeller to the motor or engine.

- Inlet and outlet ports: Openings where the fluid enters and exits the pump.

- Wear ring

- Lantern ring

- Stuffing box

- Inlet vertex

- Mechanical seal or gland packing

- Shaft sleeve

- Bearings

How centrifugal pump works?

When the pump is turned on, the impeller rotates and accelerates the fluid. The fluid is then thrown outward by centrifugal force and enters the casing. The casing is designed to slow down the fluid and convert some of its kinetic energy into pressure energy. The fluid then exits the pump through the outlet port.

How centrifugal pumps can be classified?

Centrifugal pumps can be classified according to a number of factors, including:

- Flow type: Axial, radial, or mixed flow.

- Number of stages: Single-stage or multi-stage.

- Type of volute: Single or double volute.

- Type of casing: Horizontally split, vertically split, or end-suction.

Centrifugal pumps are available in a wide range of sizes and capacities, and can be used to pump a variety of fluids, including water, sewage, chemicals, and petroleum products. They are relatively simple to operate and maintain, and are generally very efficient.

What are the advantages of centrifugal pumps?

Here are some of the advantages of using centrifugal pumps:

- They can handle a wide range of flow rates and pressures.

- They are relatively efficient and have low operating costs.

- They are simple to design and manufacture, making them relatively inexpensive.

- They are easy to operate and maintain.

What are the applications of centrifugal pumps?

Centrifugal pumps are used in a wide variety of applications, including:

- Water supply and distribution

- Sewage treatment

- Industrial processes, such as chemical processing, food processing, and power generation

- Irrigation

- Fire protection

- Mining

- Oil and gas production

What are the energy conversions take place in centrifugal pumps?

In centrifugal pumps hydraulic energy is being converted into kinetic energy.

What types of reducers are used at pump suction & discharge ends?

Suction side: Eccentric type & Discharge side: Concentric

What is the function of an impeller in centrifugal pumps?

It converts kinetic energy of pump into hydrodynamic energy by rotary motion

What is the function of pump casing?

Casing converts velocity head from impeller into pressure head & also guides the flow to the discharge end.

What are the types of pump casing?

Volute & diffusers are two different types of pump casing

What do you mean by volute?

A volute is a spiral-like geometry with an increasing through-flow area, reducing the velocity of the fluid and increasing the static pressure

What are the different types of volutes?

Single volute & Double volute

Write down the working principle of centrifugal pumps

In centrifugal pumps, fluid enters the impeller through inlet eye & exists along the circumference between the vanes of impeller. This impeller is connected to shaft & in turn to motor, this rotary motion of the impeller converts kinetic energy of the fluid into hydrodynamic energy.

What are the types of impellers?

Open impeller: As its name suggests, an open impeller has vanes that are open on both sides without any protective shroud. These are structurally weak.

These are used for low flow & low head applications. Generally used for pump solids or sludge. These require much NPSH.

Semi open impeller: Semi-open impellers have a back-wall shroud that adds mechanical strength to the vanes.

Closed impeller: Are very robust & require low NPSH

Impellers are also classified as single suction & Double suction

What are the rotary & stationary parts of the pumps?

Rotary parts:

Shaft

Impeller

Shaft sleeve

Bearings

Stationary Parts:

Pump casing

Gland packing or mechanical seal

Lantern ring

Why eccentric reducers are used at pump suction side?

To avoid air locking & cavitation eccentric reducers are used at suction side

What do you mean by the NPSH in pumps?

It is the net positive head required at pump suction to avoid cavitation

What do you understand by the term cavitation?

Cavitation is the formation & collapsing of vapor bubbles at pump’s suction

How the cavitation does affect the pump’s life?

Cavitation causes following impacts:

Vibrations in pump

Damage of impellers

Heavy noise

What are the factors considered for centrifugal pumps design?

Flow required

NPSH available & NPSH required

Total head

Pump efficiency

Fluid used

What are the materials used for pump casing?

Generally cast steel or cast iron are used for single stage centrifugal pumps

What are the materials used for Impellers?

Impellers are made up of cast iron, gun metal & stainless steel

What is the function of wear ring?

As the name indicates it protects the wear & tear of impeller

What do you mean by static suction head in pump?

The static suction head is the vertical distance from the center line of the pump to the free level of the liquid to be pumped.

What do you mean by static discharge head in pump?

Static discharge head is the vertical distance between the pump centerline and the point of free discharge or the surface of the liquid in the discharge tank.

What do you mean by total static head?

Total static head is the vertical distance between the free level of the source of supply and the point of free discharge or the free surface of the discharge liquid.

What do you mean by total head?

It is total dynamic discharge head plus total dynamic suction head

Note: If source water level is below the pump center line, then

Total head = Discharge head Suction lift

If source Water level is above the pump suction line, then

Total head = Discharge head-Suction head

What are the problems associated with centrifugal pumps?

Following are the common problems associated with pumps

Low discharge pressure

Low delivery

Cavitation

High vibrations

Pump seize

Over load

More suction lift

Air locking & No priming

What are the reasons for no delivery or no discharge in centrifugal pumps?

The main reasons can be as follows:

Air lock in pump suction

Suction valve closed

Low tank level

What are the reasons for low delivery?

Suction valve partially opened

Reverse rotation of pump

Low speed of pump

Suction strainer is chocked

What are the reasons for over load of pump?

More flow

High speed

Reverse rotation of pump

Pump discharge kept open to atmosphere

Internal friction in impeller & wear ring or impeller & casing

More tightened gland packing

No lubricant in bearing or bearing seized

What are the potential reasons for pump vibrations?

Overloading of pump

Reverse rotation of pump

Impeller rubbing inside the casing

Misalignment

Damaged bearing

Shaft run out

Shaft imbalance

Too much noise coming from pump inside, what does this mean?

Air lock in pump

Overloading of pump

Pump discharge line is less than actual required

Cavitation

No lubricant in bearings

What are the common mistakes done during pump installation?

Choosing poor foundation

Note: Pump foundation weight should be 3 to 4 times the pump weight

Lesser size suction pipe line

Lesser size discharge pipe line

Interchanging concentric & eccentric reducers

What are the safety protections & interlocks given for a centrifugal pumps?

Over load

Low load

High bearing vibrations

High bearing temperature

High suction DP

Source water level low

How do you increase the head & flow of pump by modifying impeller size?

By increasing the impeller diameter head & flow can be increased

By increasing the impeller width flow can be increased

What are the reasons for reduction of pump efficiency?

Operating the pump at lower capacity

Operating the pump at higher load

Throttling the discharge valve

Increase in impeller & wearing clearance

Lower suction head

High suction lift

Read Also

Download Free Piping PDF for Interview Preparation

Know more about Heat Exchanger

Download Free Piping PDF for Interview Preparation

What is gasket and their types

What is a valve and its types?

.